Thermal Cycling

Equipment

Thermal testing was born out of the industries increasing need to manage thermal processes and improve operations. High quality thermal cycling equipment and testing is essential when dealing with aerospace, automotive, communication, medical, and military industries.

Thermal testing chambers provide a clean, temperature controlled, environment for testing high-tech products in space simulated or high altitude conditions. Extreme environmental conditions are simulated during flight-like scenarios to re-create the operational environment that the product will experience in space. These conditions include alternate cycles of extreme heat and cold, pressure extremes, solar radiation levels, and the airless conditions of space.

Controlling temperature with precision at the device case is a major benefit of Khoury’s thermal cycling equipment like the Khoury Box thermal testing chamber. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. This process brings the device/assembly to temperature and therefore reduces soaking time. Thermal Testing interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.

- Globalization is leading to vehicles or vehicle platforms that must operate in extremely wide temperature ranges. Careful and detailed analysis of component placement and thermal shielding is required to avoid malfunction. Many components in a vehicle can become so hot that they can potentially fail, or degrade nearby components leading to serious safety and durability issues. Thermal testing works to prevent future issues.

- The communications field is growing rapidly. Controlling heat for today’s communications equipment is a key factor in design optimization for thermal performance, size, mass and environmental conditions. Thermal testing provides uniform and reliable electronics cooling, even under tight space constraints. Telephones, satellites, radar and sonar systems, and similar technologies require testing to assure they will function and function well in the times we need them the most. Thermal testing keeps the telecom industry thriving, and makes sure innovations hold up against the competition.

- The healthcare industry demands increasingly smaller, faster, and more powerful devices. This results in concentrated heat loads, which can cause performance variability, premature component failure and can even harm patients. The problems they face can affect the well being of others, so they need quality assistance in testing and treating medical instruments. Thermal testing tests the limits and safety of products before they become hazardous to the public.

Thermal cycling equipment has helped deliver thousands of solutions that operate in mission-critical applications in the harshest environmental conditions. These thermal solutions provide high-performance, high-efficiency heat transfer in this space and weight constrained application, providing reliable performance in extreme temperatures, rain, sand and snow.

Thermal Cycling Equipment

Thermal testing was born out of the industries increasing need to manage thermal processes and improve operations. High quality thermal cycling equipment and testing is essential when dealing with aerospace, automotive, communication, medical, and military industries.

Thermal testing chambers provide a clean, temperature controlled, environment for testing high-tech products in space simulated or high altitude conditions. Extreme environmental conditions are simulated during flight-like scenarios to re-create the operational environment that the product will experience in space. These conditions include alternate cycles of extreme heat and cold, pressure extremes, solar radiation levels, and the airless conditions of space.

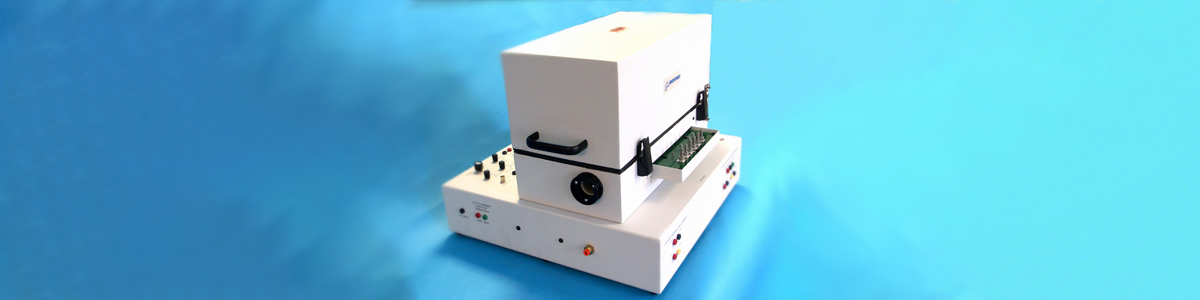

Khoury Box Thermal Cycling Details

Controlling temperature with precision at the device case is a major benefit of Khoury’s thermal cycling equipment like the Khoury Box thermal testing chamber. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. This process brings the device/assembly to temperature and therefore reduces soaking time. Thermal Testing interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.

- Globalization is leading to vehicles or vehicle platforms that must operate in extremely wide temperature ranges. Careful and detailed analysis of component placement and thermal shielding is required to avoid malfunction. Many components in a vehicle can become so hot that they can potentially fail, or degrade nearby components leading to serious safety and durability issues. Thermal testing works to prevent future issues.

- The communications field is growing rapidly. Controlling heat for today’s communications equipment is a key factor in design optimization for thermal performance, size, mass and environmental conditions. Thermal testing provides uniform and reliable electronics cooling, even under tight space constraints. Telephones, satellites, radar and sonar systems, and similar technologies require testing to assure they will function and function well in the times we need them the most. Thermal testing keeps the telecom industry thriving, and makes sure innovations hold up against the competition.

- The healthcare industry demands increasingly smaller, faster, and more powerful devices. This results in concentrated heat loads, which can cause performance variability, premature component failure and can even harm patients. The problems they face can affect the well being of others, so they need quality assistance in testing and treating medical instruments. Thermal testing tests the limits and safety of products before they become hazardous to the public.

Thermal cycling equipment has helped deliver thousands of solutions that operate in mission-critical applications in the harshest environmental conditions. These thermal solutions provide high-performance, high-efficiency heat transfer in this space and weight constrained application, providing reliable performance in extreme temperatures, rain, sand and snow.

About Khoury Industries:

About Khoury Industries:

With more than 35 years of expertise interfacing to the major ATE equipment and stand alone home made test station (Rack and Stack), KHOURY INDUSTRIES high quality thermal testing fixtures and accessories are an accurate and convenient solution. High quality thermal testing or thermal cycling equipment, wafer, Hybrids and IC’s at precisely controlled temperatures at the tester site or probing components.

Temperatures range from – 80C to +225C (Depending on your air controlled source) All THERMAL TEST FIXTURES are ESD-FREE AND OR EMI SHIELDED, most systems are available with the European CE standards. The company is headquartered in Bellingham, MA, USA and has sale representatives throughout the world.

With more than 35 years of expertise interfacing to the major ATE equipment and stand alone home made test station (Rack and Stack), KHOURY INDUSTRIES high quality thermal testing fixtures and accessories are an accurate and convenient solution. High quality thermal testing or thermal cycling equipment, wafer, Hybrids and IC’s at precisely controlled temperatures at the tester site or probing components.

Temperatures range from – 80C to +225C (Depending on your air controlled source) All THERMAL TEST FIXTURES are ESD-FREE AND OR EMI SHIELDED, most systems are available with the European CE standards. The company is headquartered in Bellingham, MA, USA and has sale representatives throughout the world.

Our Thermal Cycling Equipment & Testing Devices

ELI-1000

A Remote, Compact Testing Solution

This revolutionary system combines a thermal source and custom or standard chamber into one system. The interchangeable chamber feature of the ELI-1000 allows users to easily accommodate their varying industry needs. The patented technology in the ELI-1000 allows for a steady state operation with a heating/cooling system that can be operated and controlled independently of each other.

Khoury Box

RF, Microwave Thermal testing

Controlling temperature with precision at the device case is a major benefit of the Khoury Box thermal test fixture. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.