Thermal Testing & Cycling Solutions For Plastic & Rubber Materials

Rubber & Plastic materials need to meet appropriate durability requirements in the operating environment to ensure they protect internal components and electronics. These materials are used in a wide variety of applications such as tubing or casings across a broad range of industries including: medical, military, aerospace, manufacturing, and even communications. Our rubber & plastic thermal testing devices can help manufacturers in these industries create more effective products that withstand the test of time.

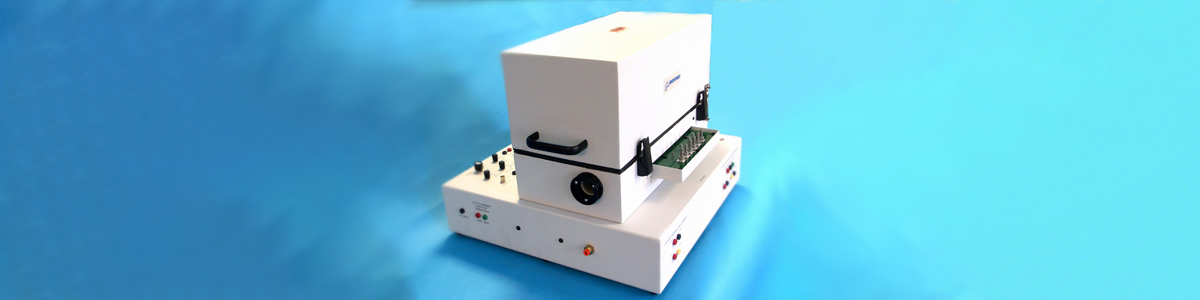

In a recent medical application, Khoury Industries assisted with a product for a customer that needed a catheter made from rubber and plastic that could withstand the variation in temperature that would allow the epoxy to cure at a specified temperature. When accurate rubber and plastic thermal testing is needed, top companies turn to Khoury Industries’ compact environmental test chambers. The Khoury Box and ELI Systems assure manufacturers that their material will perform when it’s crucial at specific temperatures.

At Khoury Industries, our goal is to provide rubber & plastic thermal testing solutions that will help manufacturing companies meet the strictest of temperature standards. Furthermore, to also allow products to adhere to required temperature guidelines. This is why our units are designed to operate in temperatures ranging from -80°C to +225°C. They provide both electronic noise free and moisture free environments. Our thermal testing units will offer an ideal solution for analyzing component failures, assessing functionality, and determining product life cycles.

Thermal Testing & Cycling Solutions For Plastic & Rubber Materials

Rubber & Plastic materials need to meet appropriate durability requirements in the operating environment to ensure they protect internal components and electronics. These materials are used in a wide variety of applications such as tubing or casings across a broad range of industries including: medical, military, aerospace, manufacturing, and even communications. Our rubber & plastic thermal testing devices can help manufacturers in these industries create more effective products that withstand the test of time.

In a recent medical application, Khoury Industries assisted with a product for a customer that needed a catheter made from rubber and plastic that could withstand the variation in temperature that would allow the epoxy to cure at a specified temperature. When accurate rubber and plastic thermal testing is needed, top companies turn to Khoury Industries’ compact environmental test chambers. The Khoury Box and ELI Systems assure manufacturers that their material will perform when it’s crucial at specific temperatures.

At Khoury Industries, our goal is to provide rubber & plastic thermal testing solutions that will help manufacturing companies meet the strictest of temperature standards. Furthermore, to also allow products to adhere to required temperature guidelines. This is why our units are designed to operate in temperatures ranging from -80°C to +225°C. They provide both electronic noise free and moisture free environments. Our thermal testing units will offer an ideal solution for analyzing component failures, assessing functionality, and determining product life cycles.

Key Plastic & Rubber Manufacturing Industry Features

Key Plastic & Rubber Manufacturing Industry Features

Industry Standard Solutions

Khoury Industries’ thermal test fixtures use an inner and outer case made from aluminum and offer thermal test chambers that provide a metallic-free environment for hot and cold temperature cycling. Khoury Industries uses a silicon rubber, Teflon, and Lexan material to construct your custom thermal solution.

Interested in learning more about our thermal testing units? Give Khoury Industries a call today at (508) 380-5709 to see how we can help you take your products to the next level. Our team is ready to assist with any questions that you may have regarding our products & offerings.

Our Thermal Testing & Cycling Devices

ELI-1000

A Remote, Compact Testing Solution

This revolutionary system combines a thermal source and custom or standard chamber into one system. The interchangeable chamber feature of the ELI-1000 allows users to easily accommodate their varying industry needs. The patented technology in the ELI-1000 allows for a steady state operation with a heating/cooling system that can be operated and controlled independently of each other.

Khoury Box

RF, Microwave Thermal testing

Controlling temperature with precision at the device case is a major benefit of the Khoury Box thermal test fixture. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.