Our Thermal Testing & Cycling Devices

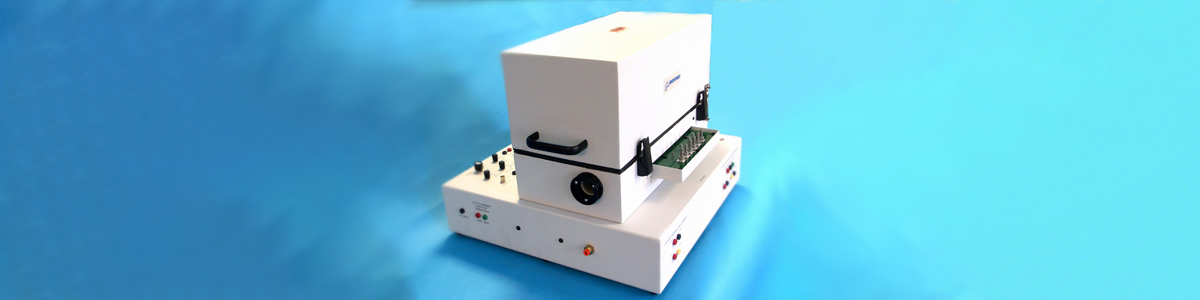

ELI-1000

A Remote, Compact Testing Solution

This revolutionary system combines a thermal source and custom or standard chamber into one system. The interchangeable chamber feature of the ELI-1000 allows users to easily accommodate their varying industry needs. The patented technology in the ELI-1000 allows for a steady state operation with a heating/cooling system that can be operated and controlled independently of each other.

Khoury Box

RF, Microwave Thermal testing

Controlling temperature with precision at the device case is a major benefit of the Khoury Box thermal test fixture. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.