Industry Related News: United States – June, 2021:

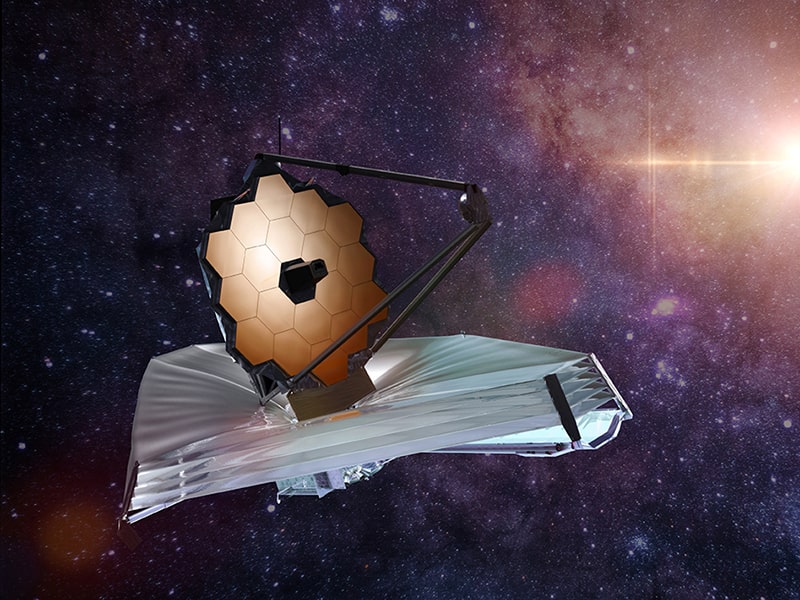

The James Webb Space Telescope, also known as Webb or JWST, will completely alter the way we view and understand space. With over 20 years of development and significantly more power than the Hubble, this revolutionary telescope offers exciting possibilities. The hope is that it will provide scientists with a more thorough understanding of the formation of the universe itself and the galaxies within it. It will also offer a glimpse into the present and future, with the ability to unveil what is happening in opaque clouds that mask the birth of stars and planets. This colossal telescope recently underwent extensive thermal testing (amongst other rigorous tests) to ensure it could survive in the depths of space once it launches later this year.

Thermal testing is instrumental in making sure that the telescope can survive the extreme temperatures of space. One side of the craft will be facing deep space, while the other will be reflecting the sun – meaning it needs to survive temperatures ranging from -235°F (-148°C) to upwards of 215°F (102°C). Thermal testing was critical in this case, as the telescope will be out of reach for repairs. If something goes wrong, the telescope could be lost forever.

As the telescope has a light-collecting area six times that of the Hubble, it had to be tested in pieces before assembly. Units were assembled across the globe, a collaboration of US, European, and Canadian intelligence, before being tested individually. Once this proved successful, the pieces were combined into two large halves. These were sent to NASA’s famous thermal chamber A, the largest of its kind in the world. Despite some concerns, the telescope passed all tests flawlessly in late 2020. Despite this, the launch had to be delayed to October 2021 from its previous March date.

Without proper thermal testing, Webb would have been unsuccessful post-launch. With technology of this caliber, the temperature must be kept within very specific ranges. This is common in many industries, even when space travel isn’t a consideration. Thermal chambers allow you to cycle a product or device through large temperature extremes in order to ensure that everything holds up. Industries ranging from Automotive to Medical all use thermal testing in order to test safety and durability. We might not all have access to NASA’s famous thermal chamber A, but Khoury Industries offers some of the best thermal testing & cycling systems on the market. From the Khoury Box to the ELI-1000 testing chamber, our products can be customized to your specific needs.

Science Focus, “James Webb Space Telescope: Inside the high-stakes testing of Hubble’s £7.2bn successor“ sciencefocus.com, May 2021, Accessed 25 May 2021.

NASA, “NASA’s James Webb Space Telescope Emerges Successfully from Final Thermal Vacuum Test” nasa.gov, May 30 2019, Accessed 25 May 2021.

ABOUT KHOURY INDUSTRIES

Khoury Industries is a worldwide leader in temperature testing equipment for device characterization, thermal cycling equipment, and failure analysis. Khoury Industries designs and manufactures custom thermal testing chambers and microwave thermal testing fixtures used in a variety of industries including: military, space, automotive, medical, research, and communication fields. The Khoury Box and the patented ELI-1000 have quickly become industry favorites as thermal testing devices used to ensure the reliability of industrial and electronic products through prolonged exposure to extreme conditions.

For more information, contact:

Penny Aicardi

Khoury Industries

5 Mechanic Street

Bellingham, MA 02019

sales@khouryindustries.com