Industry Related News: United States – December, 2020:

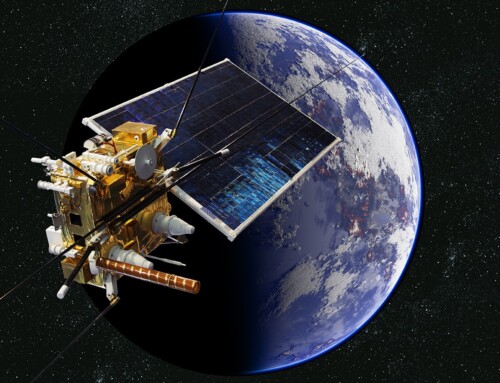

NASA’s James Webb Space Telescope has endured rigorous testing throughout the back half of 2020, hitting major milestones like its tower deployment, environmental and thermal tests, and now a deployment and tension test for the telescope’s sunshield. They are hitting their targets in order to launch the Webb Telescope in the end of October 2021.

This telescope has an intricate array of systems that need to be able to operate in the harsh conditions beyond Earth’s atmosphere. The Webb Space Telescope will be traveling in temperatures around 2.7 Kelvin, which is roughly equal to -455° F and -270.45° C, along with Sun exposure that could damage most essential electronics and sensitive infrared sensors without proper consideration and fortification. The spacecraft will depend on a mirror system in the solar-facing side of the bus as well as a mechanically deployed sunshield made of Kapton® polymer-coated membranes. The material has been created to be able to reflect light and heat away from the telescope and other systems, keeping the observation area at a workable 185° F. The Kapton® membranes were developed and thermal tested to withstand incredible temperatures to keep the rest of the craft undamaged.

A majority of the testing for the telescope is performed in an artificially cooled environment to prepare for the subzero (°F, °C) temperatures typical in outer space. The team not only performed thermal tests, but deployment and tension tests under extreme cold temperatures as well in order to prepare the craft for unforeseen conditions like having to deal with unexpected friction (simulated by Earth’s gravity, in this instance). Webb Telescope’s sunshield was deployed using 139 actuators, eight motors, and thousands of components to unfold and stretch the five membranes of the sunshield into its final kite-like shape. The team has designed each of the five membranes to operate and tension independently of one another, which also gives the sunshield a better chance of surviving a malfunction with one of the systems.

Every piece of machinery, from simple consumer semiconductors to telescopes with 139 actuators, requires thermal testing. With such extensive environmental testing, NASA plans on the James Webb Space Telescope launching on schedule and spending years exploring space and sending fascinating new data during its journey. With high marks in every test and simulation so far, the future looks bright for the telescope in 2021.

NASA, “NASA’s Webb Sunshield Successfully Unfolds and Tensions in Final Tests“ nasa.gov, December 2020, Accessed 28 December 2020.

NASA, “NASA’s Webb Completes Significant Testing Milestone for Deployable Tower“ nasa.gov, November 2020, Accessed 28 December 2020.

NASA, “NASA’s James Webb Space Telescope Completes Environmental Testing“ nasa.gov, October 2020, Accessed 28 December 2020.

ABOUT KHOURY INDUSTRIES

Khoury Industries is a worldwide leader in temperature testing equipment for device characterization, thermal cycling equipment, and failure analysis. Khoury Industries designs and manufactures custom thermal testing chambers and microwave thermal testing fixtures used in a variety of industries including: military, space, automotive, medical, research, and communication fields. The Khoury Box and the patented ELI-1000 have quickly become industry favorites as thermal testing devices used to ensure the reliability of industrial and electronic products through prolonged exposure to extreme conditions.

For more information, contact:

Penny Aicardi

Khoury Industries

5 Mechanic Street

Bellingham, MA 02019

[email protected]