Microwave testing wave guides

RF / Microwave

Temperature Testing

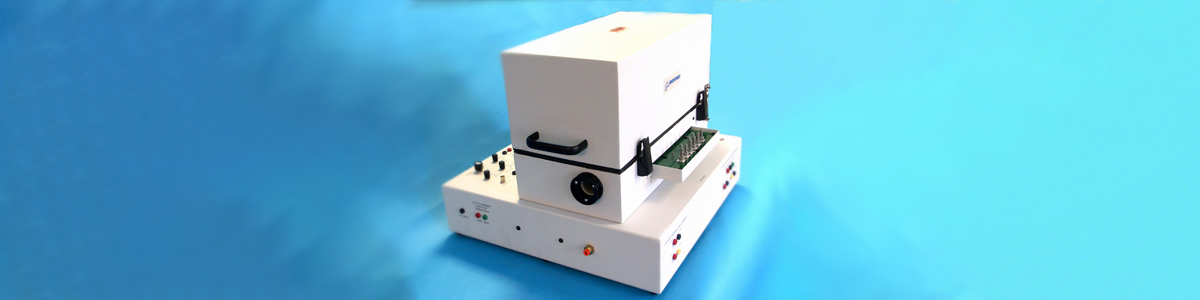

RF / Microwave Temperature Testing – Controlling temperature with precision at the device case is a major benefit of the Khoury Box Thermal Test Fixture designed for optimal temperature testing. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. This process brings the device/assembly to temperature and therefore reduces soaking time. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.

- RF/Microwave Temperature Testing Clam Shell Design

- Interface to Your Tester or any major ATE tester or rack & stack test system.

- Improve test accuracy with a controlled thermal test environment (noise-free, ice and frost-free, ESD-free).

- Complete tester interface includes mechanical and electrical interface fixturing and electronics ensuring

- RF/Microwave Temperature Testing offering true and accurate test signals to and from the DUT.

- Optional see-through window to monitor probe or deliver an RF signal to your DUT while testing.

- Two DB9 connectors, 10 SMA feed through connections, and 2 thermocouples to monitor and

- control ambient and/or case temperature. Test engineer has full control of internal electronics with Bi-directional capability.

- Supports multiple DUT’s simultaneously.

- Can work with any thermal source and has an operating temperature range of -90°C to 225

RF / Microwave Temperature Testing

RF / Microwave Temperature Testing – Controlling temperature with precision at the device case is a major benefit of the Khoury Box Thermal Test Fixture designed for optimal temperature testing. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. This process brings the device/assembly to temperature and therefore reduces soaking time. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.

The Khoury Box Test Fixture

- RF/Microwave Temperature Testing Clam Shell Design

- Interface to Your Tester or any major ATE tester or rack & stack test system.

- Improve test accuracy with a controlled thermal test environment (noise-free, ice and frost-free, ESD-free).

- Complete tester interface includes mechanical and electrical interface fixturing and electronics ensuring

- RF/Microwave Temperature Testing offering true and accurate test signals to and from the DUT.

- Optional see-through window to monitor probe or deliver an RF signal to your DUT while testing.

- Two DB9 connectors, 10 SMA feed through connections, and 2 thermocouples to monitor and

control ambient and/or case temperature. Test engineer has full control of internal electronics with Bi-directional capability. - Supports multiple DUT’s simultaneously.

- Can work with any thermal source and has an operating temperature range of -90°C to 225

About Khoury Industries:

Your RF/Microwave Temperature Testing Experts

About Khoury Industries:

Your RF/Microwave Temperature Testing Experts

With more than 35 years of expertise interfacing to the major ATE equipment and stand alone home made test station (Rack and Stack), KHOURY INDUSTRIES thermal testing fixtures and accessories are an accurate and convenient solution. Thermal testing or cycling components, wafer, Hybrids and IC’s at precisely controlled temperatures at the tester site or probing components.

Temperatures range from – 80C to +225C (Depending on your air controlled source) All THERMAL TEST FIXTURES are ESD-FREE AND OR EMI SHIELDED, most systems are available with the European CE standards. The company is headquartered in Bellingham, MA, USA and has sale representatives throughout the world.

With more than 35 years of expertise interfacing to the major ATE equipment and stand alone home made test station (Rack and Stack), KHOURY INDUSTRIES thermal testing fixtures and accessories are an accurate and convenient solution. Thermal testing or cycling components, wafer, Hybrids and IC’s at precisely controlled temperatures at the tester site or probing components.

Temperatures range from – 80C to +225C (Depending on your air controlled source) All THERMAL TEST FIXTURES are ESD-FREE AND OR EMI SHIELDED, most systems are available with the European CE standards. The company is headquartered in Bellingham, MA, USA and has sale representatives throughout the world.

Our Thermal Testing & Cycling Devices

ELI-1000

A Remote, Compact Testing Solution

This revolutionary system combines a thermal source and custom or standard chamber into one system. The interchangeable chamber feature of the ELI-1000 allows users to easily accommodate their varying industry needs. The patented technology in the ELI-1000 allows for a steady state operation with a heating/cooling system that can be operated and controlled independently of each other.

Khoury Box

RF, Microwave Thermal testing

Controlling temperature with precision at the device case is a major benefit of the Khoury Box thermal test fixture. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.