Ensuring Pharmaceutical Products & Medical Devices Meet Strict Thermal Testing Requirements

Khoury Industries provides medical thermal testing fixtures and enclosures to the medical industry and pharmaceutical companies to provide the highest quality equipment and medications. Thermal testing fixtures and enclosures allow the precision necessary in designing and building life-saving equipment in addition to implantable and surgical devices.

Temperature test enclosures are helping the medical and healthcare industries to develop new medical solutions and the most technologically advanced health products for the community. Temperature analysis ensures their products are meeting the high demand for certainty and efficiency required for patients of the world.

Thermal testing is critical in testing the reliability in numerous medical technologies including:

• CT, PET, MRI, X-Ray, SPECT, and OCT Scanners

• Laser and LED Photonics typically used in surgery, diagnostics, ophthalmology, dermatology, dentistry, and imaging

Medical/pharmaceutical companies have traditionally used industrial ovens for hot and cold applications, but Khoury Industries has proved reliable, accurate testing through custom Khoury Box designs that are more convenient, accurate, and user-friendly.

Ensuring Pharmaceutical Products & Medical Devices Meet Strict Thermal Testing Requirements

Khoury Industries provides medical thermal testing fixtures and enclosures to the medical industry and pharmaceutical companies to provide the highest quality equipment and medications. Thermal testing fixtures and enclosures allow the precision necessary in designing and building life-saving equipment in addition to implantable and surgical devices.

Temperature test enclosures are helping the medical and healthcare industries to develop new medical solutions and the most technologically advanced health products for the community. Temperature analysis ensures their products are meeting the high demand for certainty and efficiency required for patients of the world.

Thermal testing is critical in testing the reliability in numerous medical technologies including:

• CT, PET, MRI, X-Ray, SPECT, and OCT Scanners

• Laser and LED Photonics typically used in surgery, diagnostics, ophthalmology, dermatology, dentistry, and imaging

Medical/pharmaceutical companies have traditionally used industrial ovens for hot and cold applications, but Khoury Industries has proved reliable, accurate testing through custom Khoury Box designs that are more convenient, accurate, and user-friendly.

Key Medical Research Industry Features

Key Medical Research Industry Features

Industry Standard Medical Thermal Testing Solutions

Successful medical research, testing, and procedures depend on having properly tested equipment. Khoury Industries tests surgical lasers and scanning equipment such as X-Rays and MRI machines with top thermal test equipment to ensure that the product offers optimal results and performance.

Even in applications where testing requires temperatures in excess of ±100°C, our chambers are designed to allow the highest level of productivity in the area of thermal cycling times and stability while providing the necessary interface and control to special electronic instrumentation or Automatic Test Equipment.

Our Thermal Testing & Cycling Devices

ELI-1000

A Remote, Compact Testing Solution

This revolutionary system combines a thermal source and custom or standard chamber into one system. The interchangeable chamber feature of the ELI-1000 allows users to easily accommodate their varying industry needs. The patented technology in the ELI-1000 allows for a steady state operation with a heating/cooling system that can be operated and controlled independently of each other.

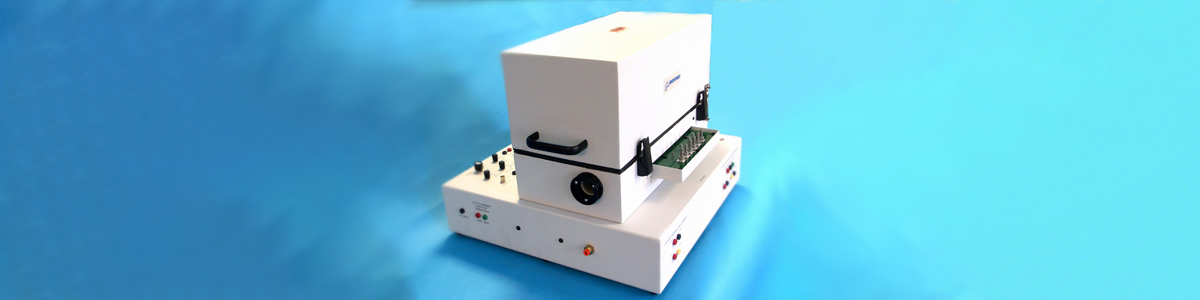

Khoury Box

RF, Microwave Thermal testing

Controlling temperature with precision at the device case is a major benefit of the Khoury Box thermal test fixture. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.