Thermal Testing & Cycling Solutions For Fiber Optic Products & Components

Fiber Optics are becoming increasingly popular given their advantages over electrical cables. These flexible, transparent fibers are created by drawing glass or plastic to diameters that allow higher data transmission speeds than its electrical counterpart. Fiber Optics Thermal Testing is critical to determining the overall functionality and longevity and is undoubtedly necessary with high-performance being the calling card of the industry. Our testing units will allow manufacturers to produce fiber optics and connections with low loss performance at both anticipated and extreme temperatures.

Fiber optics are used in internet applications, satellites, and flight and aerospace systems that demand that the components reliably function at a temperature of -55˚C to 125˚C to meet military specifications (883C). Our thermal testing units will help determine this reliability in environments that demand top-level performance.

Khoury Industries provides quality solutions for even stricter fiber optic thermal testing at ranges from -100˚C to 300˚C and any temperature in between with +/- 1 degree of accuracy. We strive to offer fiber optics thermal testing solutions that will help manufacturers meet the high-level demands of their customers. Our testing units provide both electronic noise-free and moisture-free environments. Both our Khoury Box and ELI Systems will offer an ideal solution for analyzing component failures, assessing functionality, and determining product life cycles.

Thermal Testing & Cycling Solutions For Fiber Optic Products & Components

Fiber Optics are becoming increasingly popular given their advantages over electrical cables. These flexible, transparent fibers are created by drawing glass or plastic to diameters that allow higher data transmission speeds than its electrical counterpart. Fiber Optics Thermal Testing is critical to determining the overall functionality and longevity and is undoubtedly necessary with high-performance being the calling card of the industry. Our testing units will allow manufacturers to produce fiber optics and connections with low loss performance at both anticipated and extreme temperatures.

Fiber optics are used in internet applications, satellites, and flight and aerospace systems that demand that the components reliably function at a temperature of -55˚C to 125˚C to meet military specifications (883C). Our thermal testing units will help determine this reliability in environments that demand top-level performance.

Khoury Industries provides quality solutions for even stricter fiber optic thermal testing at ranges from -100˚C to 300˚C and any temperature in between with +/- 1 degree of accuracy. We strive to offer fiber optics thermal testing solutions that will help manufacturers meet the high-level demands of their customers. Our testing units provide both electronic noise-free and moisture-free environments. Both our Khoury Box and ELI Systems will offer an ideal solution for analyzing component failures, assessing functionality, and determining product life cycles.

Key Fiber Optic Industry Features

Key Fiber Optic Industry Features

Customizable & Controlled Thermal Testing Units Built To Suit Your Needs

Our thermal testing units allow for easy testing in controlled conditions to determine the durability, performance, and functionality of fiber optics. These units can also be customized and modified to apply to your specific testing needs.

Interested in learning more about our thermal testing units? Give Khoury Industries a call today at (508) 380-5709 to see how we can help you take your products to the next level. Our team is ready to assist with any questions that you may have regarding our products & offerings.

Our Thermal Testing & Cycling Devices

ELI-1000

A Remote, Compact Testing Solution

This revolutionary system combines a thermal source and custom or standard chamber into one system. The interchangeable chamber feature of the ELI-1000 allows users to easily accommodate their varying industry needs. The patented technology in the ELI-1000 allows for a steady state operation with a heating/cooling system that can be operated and controlled independently of each other.

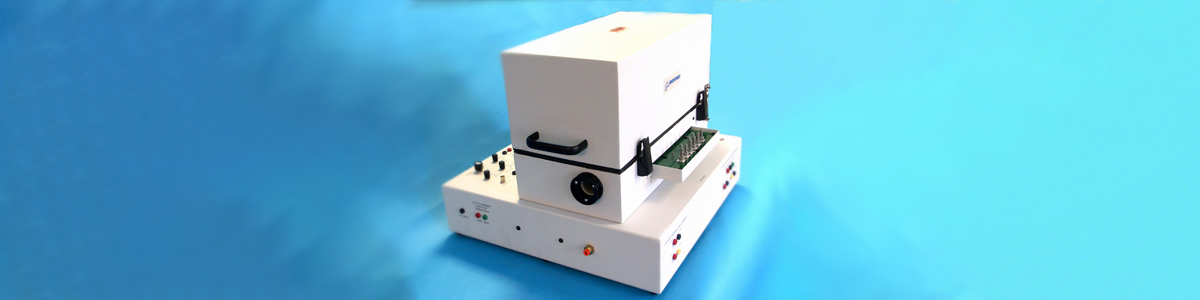

Khoury Box

RF, Microwave Thermal testing

Controlling temperature with precision at the device case is a major benefit of the Khoury Box thermal test fixture. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.