Wide Temperature Ranges For Automotive Thermal Testing Applications

Automobile manufacturers not only provide transportation of its occupants, but now offer enhanced solutions for safety, ride enjoyment, entertainment, and fuel efficiency. Both automotive manufacturers and part suppliers have become heavily dependent on electronic control units to provide these high-demand options in today’s cars.

Our automotive thermal testing fixtures allow for manufacturers to quickly test their specific applications by providing a temperature cycling test chamber that allows for high volume capacity. These enclosures also ensure solutions to specifically target their specific part.

Automobile manufacturers are making strides in passenger safety, multi-channel air conditioning and heating, fuel efficiency, entertainment options, batteries and power supply, and more. As a result, they are dependent on receiving the proper electronic control units to provide these high-demand options for future vehicles.

Our thermal cycling fixtures allow for manufacturers to quickly test their specific applications by providing enclosures that allow for high volume capacity. These enclosures also ensure solutions to specifically target their specific part.

Wide Temperature Ranges For Automotive Thermal Testing Applications

Automobile manufacturers not only provide transportation of its occupants, but now offer enhanced solutions for safety, ride enjoyment, entertainment, and fuel efficiency. Both automotive manufacturers and part suppliers have become heavily dependent on electronic control units to provide these high-demand options in today’s cars.

Our automotive thermal testing fixtures allow for manufacturers to quickly test their specific applications by providing a temperature cycling test chamber that allows for high volume capacity. These enclosures also ensure solutions to specifically target their specific part.

Automobile manufacturers are making strides in passenger safety, multi-channel air conditioning and heating, fuel efficiency, entertainment options, batteries and power supply, and more. As a result, they are dependent on receiving the proper electronic control units to provide these high-demand options for future vehicles.

Our thermal cycling fixtures allow for manufacturers to quickly test their specific applications by providing enclosures that allow for high volume capacity. These enclosures also ensure solutions to specifically target their specific part.

Key Automotive Industry Features

Key Automotive Industry Features

All Thermal Test Fixtures are ESD-Free and/or EMI Shielded, and most systems are available with European CE standards. Our systems provide an electrical noise-free, moisture-free environment. The Khoury Box boasts 50-ohm impedance-matched connections and shielded signal paths used in the tester interface which provide clear, accurate signals between the tester and the device-under-test.

All Thermal Test Fixtures are ESD-Free and/or EMI Shielded, and most systems are available with European CE standards. Our systems provide an electrical noise-free, moisture-free environment. The Khoury Box boasts 50-ohm impedance-matched connections and shielded signal paths used in the tester interface which provide clear, accurate signals between the tester and the device-under-test.

Our Thermal Testing & Cycling Devices

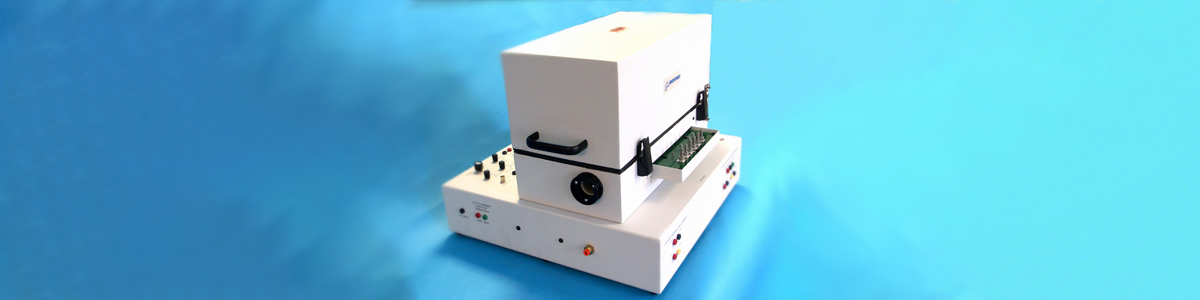

ELI-1000

A Remote, Compact Testing Solution

This revolutionary system combines a thermal source and custom or standard chamber into one system. The interchangeable chamber feature of the ELI-1000 allows users to easily accommodate their varying industry needs. The patented technology in the ELI-1000 allows for a steady state operation with a heating/cooling system that can be operated and controlled independently of each other.

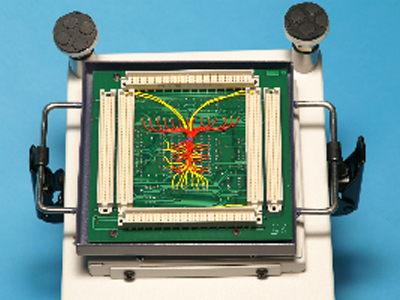

Khoury Box

RF, Microwave Thermal testing

Controlling temperature with precision at the device case is a major benefit of the Khoury Box thermal test fixture. The DUT is isolated in a localized enclosure (at temperature) with the thermal air circulated around the device under test or DUT. Tester interface utilizes impedance-matched connections to ensure true and accurate test signals between the tester, the thermal test fixture, and the DUT.